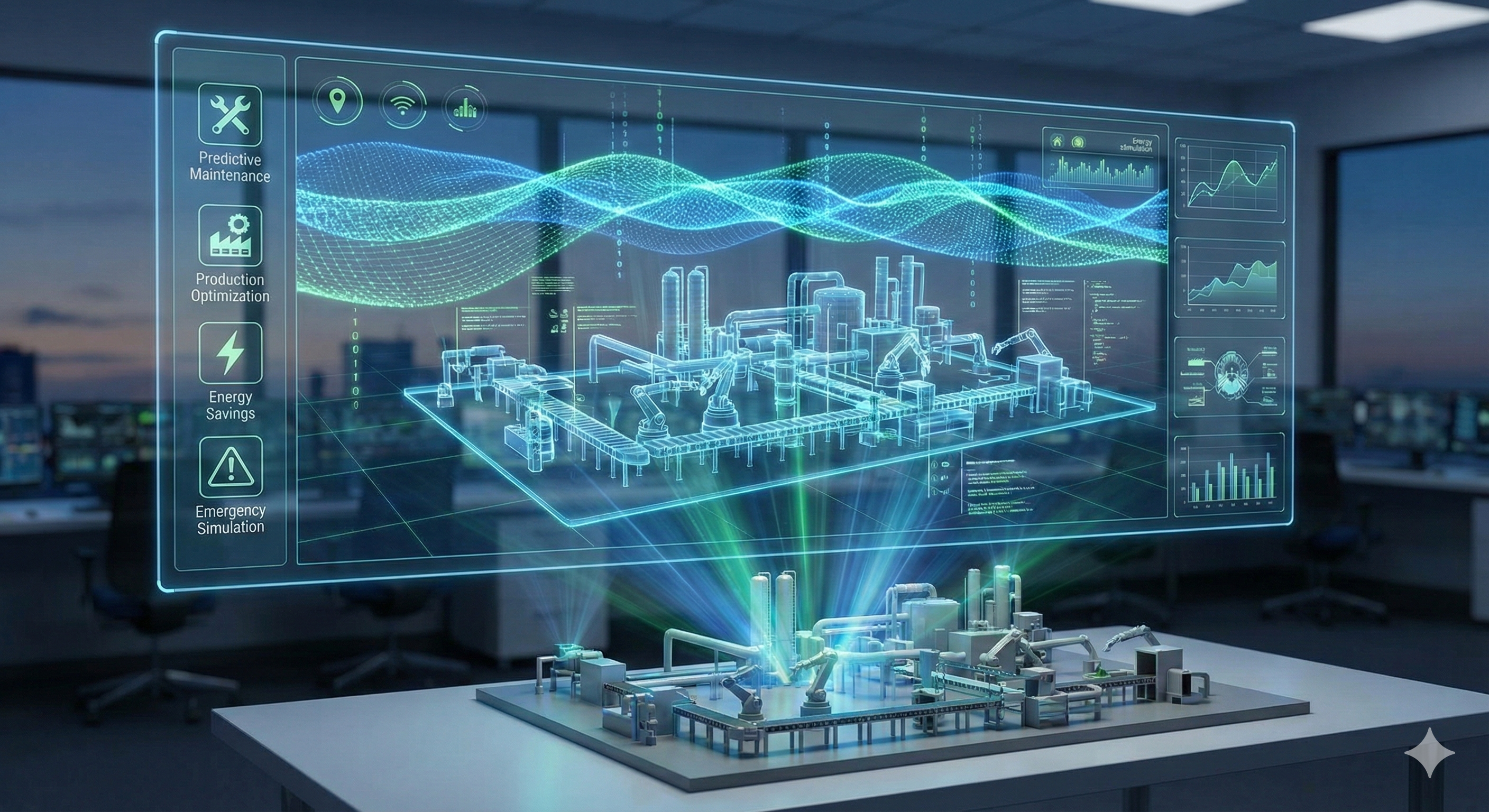

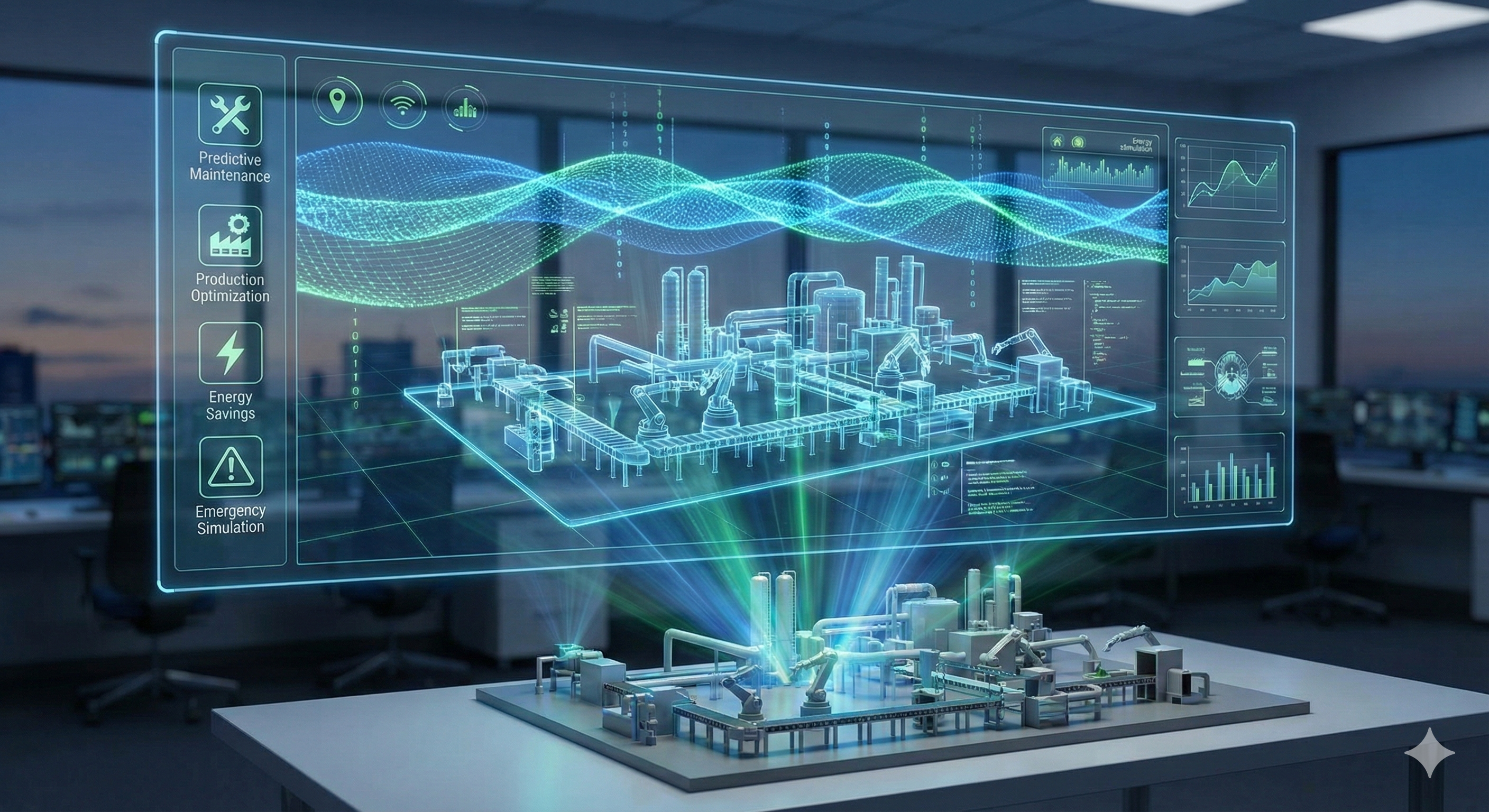

Living Digital Twins for Real-world Operations

Duora turns factories, grids, and supply chains into intelligent digital twins that optimize operations in real time, reducing downtime, lowering energy consumption, and increasing throughput.

See how our intelligent twin fabric connects data, models assets, and activates real-time optimization.

What Duora Delivers

A platform built around the intelligent digital twin

Duora is a platform built around the principles of the intelligent digital twin—unifying OT, IT, and engineering data into a governed twin fabric that stays continuously aligned with real operations.

Operations-intensive enterprises

Manufacturing and industrial operations teams

Energy and utilities asset owners

Smart building and facilities managers

Logistics networks, ports, and smart city leaders

Operations-intensive enterprises

20–30% fewer unplanned stoppages through predictive maintenance

5–10% throughput uplift without new capex

10–15% lower energy use and 10–20% lower maintenance cost

Faster ramp-up despite labor gaps and retirements

New to intelligent digital twins?

Understand how intelligent digital twins differ from traditional simulation and monitoring—and why they are becoming the operating model for modern industry.

Why operations leaders are embracing intelligent digital twins

The physical world is getting harder to run by gut, spreadsheets, and disconnected dashboards.

Production volatility, labor shortages, aging infrastructure, and tighter ESG expectations are forcing leaders to rethink how operations are run. The intelligent digital twin model provides a way to continuously understand, test, and improve performance - before problems hit the real world.

What's keeping you up at night?

Unplanned line stoppages and rising scrap

Outages, safety incidents, and regulatory risk

Energy waste you can't see until bills arrive

Critical knowledge walking out the door with retirements

What you actually want

Predictable throughput and OEE, even in volatile conditions

Engineered reliability across grids, plants, and buildings

Real-time insight into energy and asset health

A single operational "brain" that keeps learning from every shift

How Duora transforms your operations into an intelligent living model.

Our platform creates a digital twin fabric that binds together real-world assets, processes, and data streams into a single intelligent system. Instead of building custom solutions from scratch, you get a configurable platform with proven industry accelerators.

Platform

Core twin fabric

Our subscription platform ingests industrial data, models assets and processes, and supports simulation, analytics, and real-time monitoring via configurable dashboards and APIs.

Industry accelerators

80% ready, 20% configurable

Pre-built accelerators for manufacturing, energy, buildings, logistics, and cities ship with templates for common assets, KPIs, and workflows—so your team sees value in weeks, not years.

Services and managed operations

From pilot to always-on operations

Our engineering team supports integration with SCADA, MES, ERP, and IoT systems, configures models, and can operate the environment with SLAs and ongoing optimization—without becoming a custom development shop.

View Platform Overview

Solve concrete problems with ready-to-run solutions.

1.

Predictive Maintenance

Spot failures before they stop production.

Predict bearing and motor issues days or weeks ahead

Reduce emergency call-outs and overtime

Extend asset life with condition-based maintenance

2.

Energy Optimization

3.

OEE and Throughput Optimization

4.

Asset Performance Management

5.

Supply Chain & Logistics Twin

6.

Grid & Infrastructure Twin

Used by Operations-intensive Industries

Manufacturing

Optimize lines, quality, and maintenance

Process manufacturing, discrete assembly, pharma, chemicals, and food & beverage operations use Duora to improve OEE, predict failures, and reduce waste.

Proven Results at Scale.

Duora deployments consistently deliver measurable value across diverse operating environments, from single sites to global enterprise rollouts.

Operations Performance

25% average improvement in unplanned downtime

8% throughput gains within 6 months

15% maintenance cost reduction through predictive strategies

40% faster problem identification and resolution

Energy & Sustainability

12% energy reduction without production impact

20% lower carbon footprint through optimization

$500K+ annual savings per major facility

ROI in 8-12 months for most implementations

Risk & Compliance

60% reduction in safety incidents

95% faster regulatory reporting

Zero unplanned outages in critical infrastructure pilots

99.8% system uptime with managed services

Trusted by Fortune 500 manufacturers, utilities, and infrastructure operators throughout North America and Europe.

Built for how operations teams actually work.

Our platform delivers a digital twin fabric that unifies real-world assets, processes, and data streams into one intelligent system. Rather than building custom solutions from scratch, teams use a configurable platform with proven industry accelerators.

Operations Managers

Monitor KPIs across sites, get automated alerts for deviations, and run scenario planning for shift changes or demand fluctuations.

Maintenance Teams

Receive predictive alerts for asset health, prioritize work orders based on criticality, and track maintenance effectiveness over time.

Energy Managers

Track real-time energy consumption, identify optimization opportunities, and automate demand response during peak pricing periods.

Plant Engineers

Run process simulations, validate improvement ideas before implementation, and analyze root causes of quality or performance issues.

Site Leadership

Access executive dashboards with site-wide performance, benchmark against other facilities, and make data-driven capital planning decisions.

Operations Managers

Monitor KPIs across sites, get automated alerts for deviations, and run scenario planning for shift changes or demand fluctuations.

The Bottom Line

Duora is a platform built around the intelligent digital twin model, helping operations-intensive enterprises turn fragmented industrial data into a unified, decision-ready twin fabric. It continuously models real-world assets, lines, and sites so teams can monitor conditions, simulate scenarios, and predict failures and bottlenecks before they impact operations. Organizations typically start with focused use cases such as predictive maintenance, production optimization, energy savings, or emergency simulation, and expand across assets and sites over time.

What is an Intelligent Digital TwinFrequently Asked Questions

See pricing and deployment options

Ready to see how an intelligent digital twin can transform your operations?

Start with one site, asset, or problem. Expand as the twin proves its value.