Manufacturing digital twins for reliable, high-performance operations

Model your production lines, assets, and energy flows as living digital twins—so you can prevent downtime, remove bottlenecks, and run more predictable manufacturing operations.

Manufacturing is under constant pressure

Manufacturing teams are expected to deliver higher output, better quality, and lower cost—often with aging equipment, volatile demand, rising energy prices, and fewer experienced operators on the floor.

What's creating pressure

Unplanned line stoppages that disrupt schedules and customer commitments

Bottlenecks that shift week to week and are hard to diagnose

Reactive maintenance driven by alarms instead of early signals

Energy costs that spike without clear visibility into root causes

Critical operational knowledge locked in a few experts—or lost entirely

The digital twin advantage

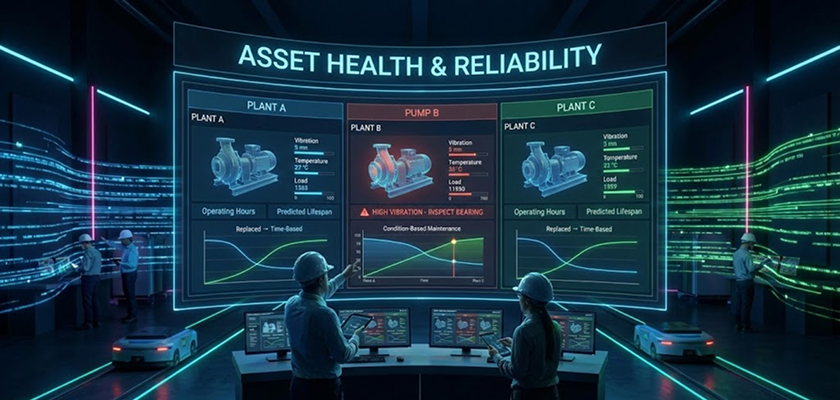

Prevent failures before they stop production

Identify true bottlenecks and test solutions safely

Move from reactive to predictive maintenance

Optimize energy use without compromising output

Capture and scale operational expertise

From firefighting to foresight

In manufacturing, an intelligent digital twin acts as a living model of how your plant actually behaves—not how it's supposed to behave on paper.

It continuously reflects:

The condition of machines and assets

How lines, buffers, and constraints interact

How energy use changes with schedules and demandHow small issues propagate into missed targets

Instead of reacting after KPIs drop, teams can:

Detect emerging failures days or weeks earlier

Test line changes or maintenance timing virtually

Understand trade-offs between throughput, cost, and risk

Make decisions with confidence before touching the real floor

Manufacturing use cases powered by intelligent digital twins

Used across the plant, Not just by specialists

Plant managers

Start each day with a live view of line health and constraints

See which issues threaten today's plan—and which don't

Evaluate trade-offs before changing schedules or priorities

Reliability & maintenance engineers

Track degradation trends across critical assets

Simulate maintenance timing to minimize production impact

Focus effort where risk and cost are highest

Continuous improvement & process engineers

Test improvement ideas virtually before rolling them out

Understand how local changes affect the full system

Validate gains with real operational data

What manufacturers typically target

While results vary by environment and starting point, manufacturing teams often aim for:

20–30%

Reduction in unplanned downtime

5–10%

Throughput uplift without major capex

10–20%

Reduction in maintenance cost

Lower

Energy intensity per unit

More stable schedules and fewer last-minute disruptions. The biggest gains usually come from eliminating chronic issues—not chasing one-off optimizations.

Start with one line. Prove value. Scale plant-wide.

Start

Choose a critical line, bottleneck process, or high-failure asset.

Prove

Baseline current performance and validate early insights using live data.

Scale

Expand to additional lines, assets, or plants—reusing what works instead of starting over.

Common questions from manufacturing teams

See what an intelligent digital twin could change in your plant

Start with one manufacturing problem that matters—and build from there.